Description

Product Description

TDF flange forming machine is one of the two major systems for ventilation duct connection in the world. This and our other products lock forming machine, duct bending machine, cutting machine, duct coner installation machine, electric coiling machine, and hydraulic lock forming machine can make up a duct production line, and the quality standards and reliability of the ducts made are reliable. Air duct quality standards are reliable.

Performance Feature

Designed through detailed research and studies to ensure the machine’s integrity, reliability, and simple, convenient operation; Unrivaled performance and price advantage; Duct and flange are integrally molded, eliminating the need for flanges and connection processes. This improves product quality and reduces manufacturing costs; No weld joints, no machinery, assembly as simple as just 4 screws, easy and quick working, high efficiency; Beautiful overall appearance of the duct after installation, smooth lines and good sealing performance.

Machine Parameters

Machine Parameters:

| Model | Power | Thickness | Material Strength | Weight(kg) | Dimension(mm) |

| T-12 | 3kw | 0.5-1.2mm | 35±0.5 | 1000 | 2900*700*1100 |

| T-15 | 4kw | 0.8-1.5mm | 35+0.5 | 1200 | 2900*700*1100 |

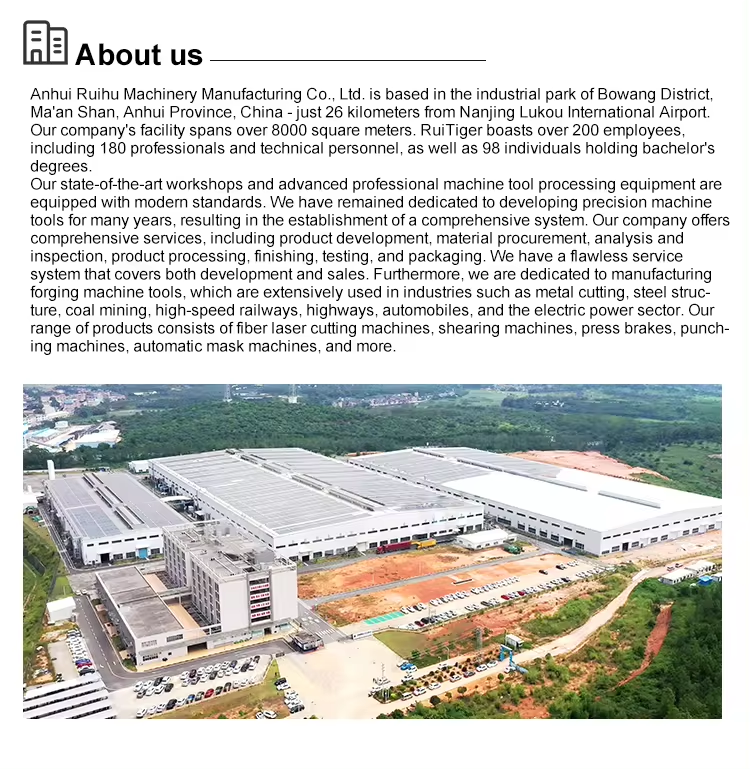

Q:Is your company a trader or a factory?

A:We are a factory and have an independent trading department.

Q:Where is your company? Can I come and visit?

A:Our company is located in Maanshan City, Anhui Province, China, welcome to visit us.

Q:What is your payment method?

A:Bank transfer, or Alibaba online payment.

Q:Does your company provide after-sales service? What kind of after-sales service?

A:We provide one year warranty service and free replacement of non-man-made damaged parts.

Q:How long does it take to receive a reply to my inquiry?

A:We will reply your inquiry within 24 hours (working days).

Q:What are your working hours?

A:9am-5pm (weekdays).

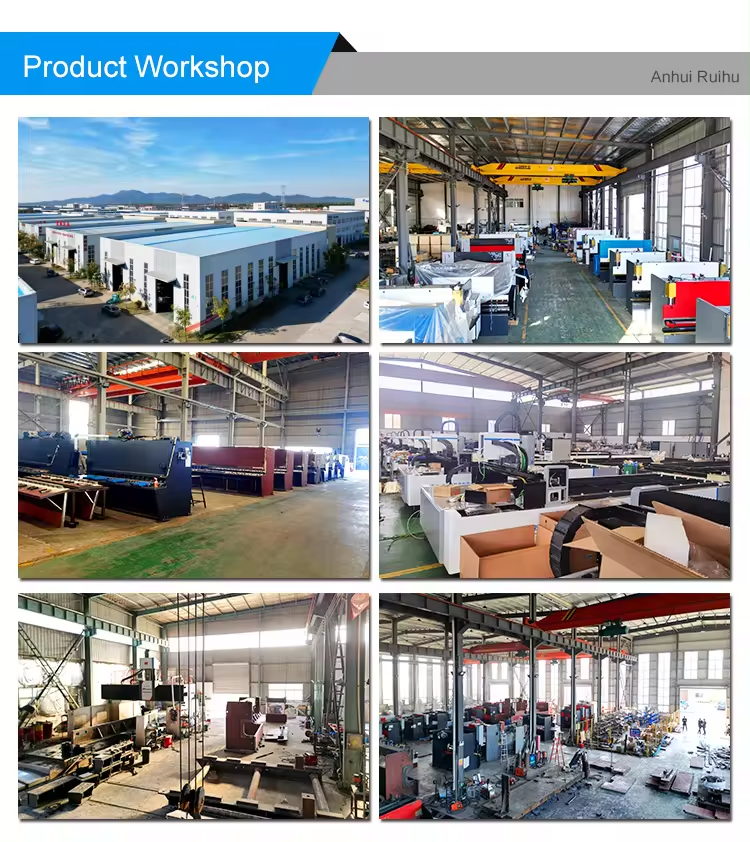

Q:How is your quality control?

A:Every machine that comes out of the factory will go through strict testing to ensure that it reaches the customer and can be used normally.

Q:Do you support customization? Can I put my logo on the product?

A:Yes.

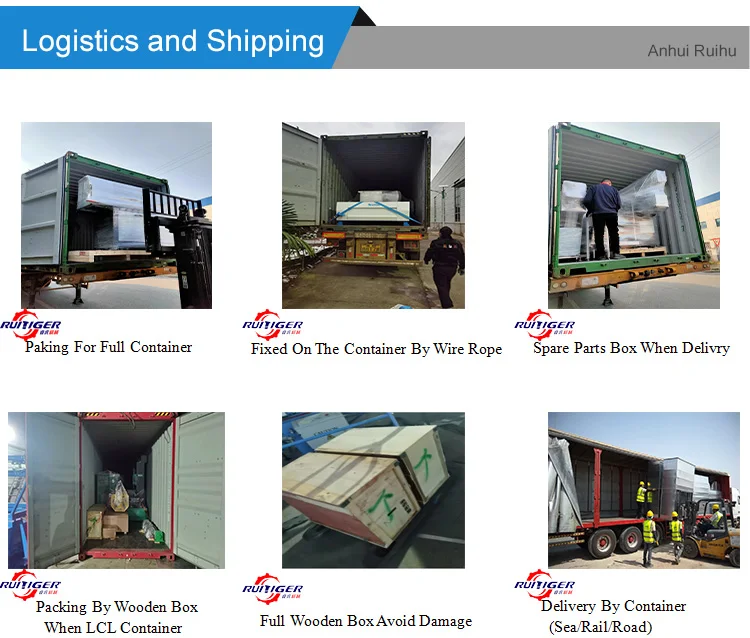

Q:What is the packaging of the product?

A:The machine is wrapped in plastic material and placed inside a customized wooden box.

Q:What is the minimum order quantity?

A:One piece.

Q:What information do I need to provide to get a quote? Do you have a quotation for the products?

A:Please provide the approximate length and thickness of the workpiece to be processed, please contact our customer service for details.

Q:How long is the delivery time?

A:Production is completed within two weeks.