Description

Feature:

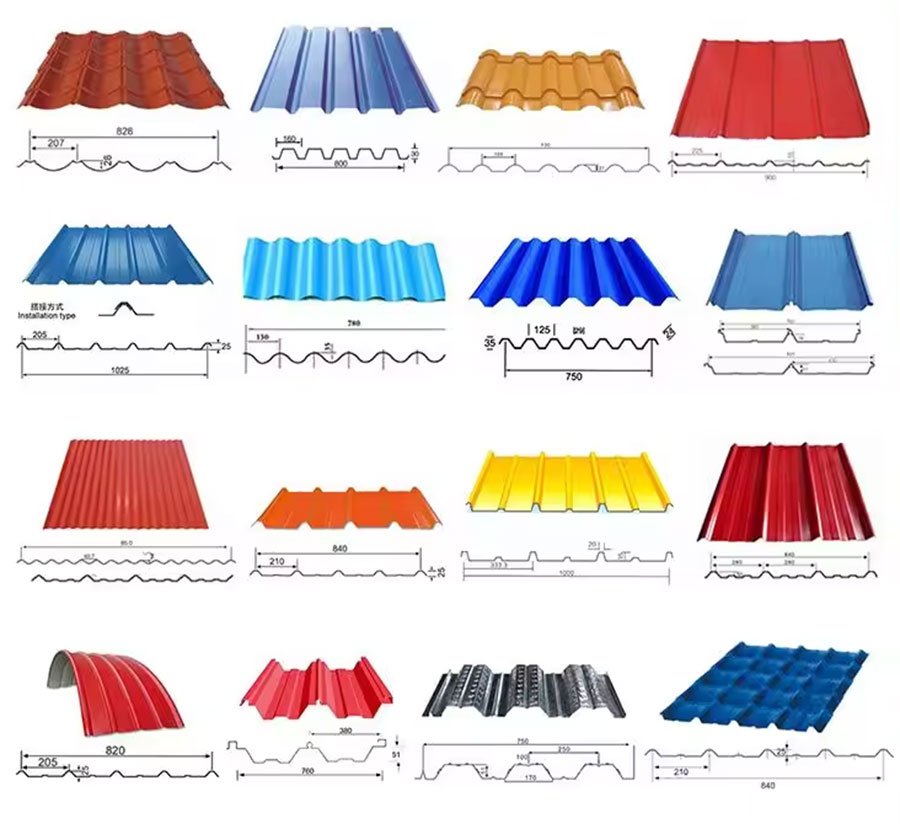

1. Straight and Tapered Profile in one machine

2. Smart body,available to fix in 20GP container,easy transport to the site

3. Can be customized to only straight profile or only tapered profile in one machine

4. Easy operation,low maintain cost

2. Smart body,available to fix in 20GP container,easy transport to the site

3. Can be customized to only straight profile or only tapered profile in one machine

4. Easy operation,low maintain cost

Technical parameters of corrugated steel plate rolling machine:

|

Main Technical Data

|

|

|

Size

|

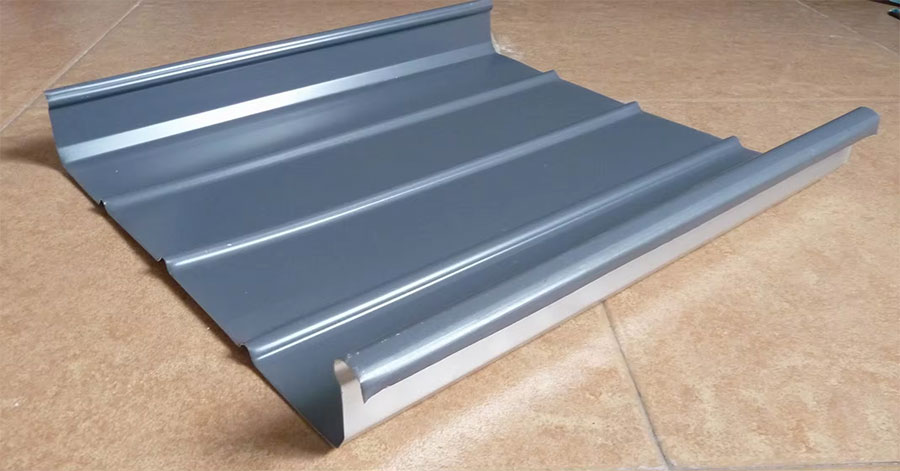

YX65-400-425

|

|

Dimension

|

5800*1600*1500mm

|

|

Motor Power

|

7.5KW*2

|

|

Hydraulic Power

|

2.2KW

|

|

Forming Steps

|

13Steps

|

|

Forming Speed

|

8-15m/min

|

|

Voltage

|

380V/50HZ/3PH

|

|

Effective Width

|

400mm,425mm

|

|

Material Width

|

575mm,600mm

|

|

Height of Roofing

|

65mm

|

|

Aluminum Thickness

|

0.7-1.0mm

|

|

Steel Thickness

|

0.5-0.8mm

|

|

Control System

|

PLC Control

|