Description

Product Description

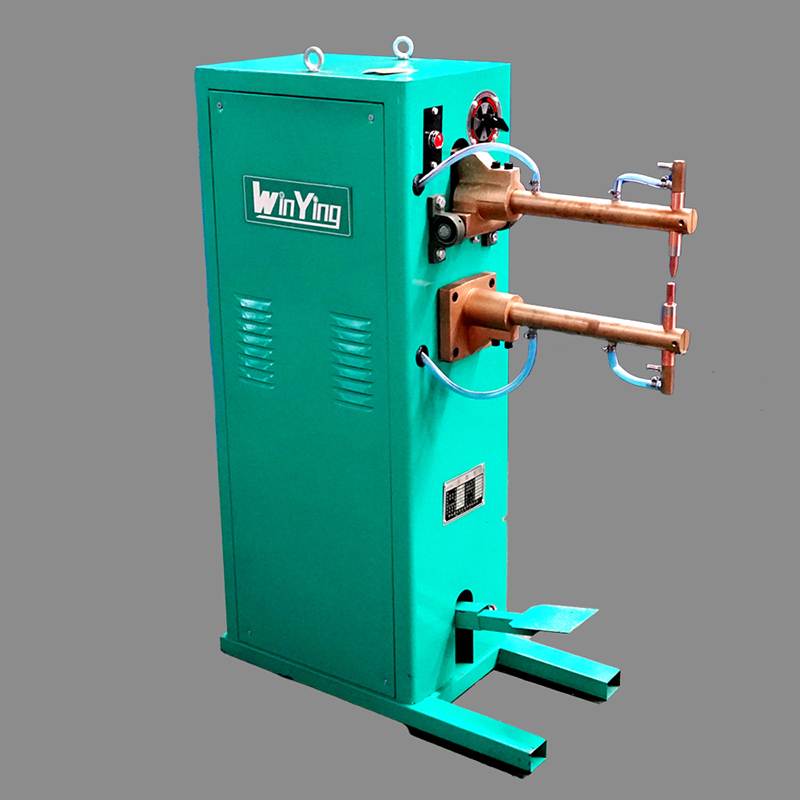

The electric spot welding machine adopts the principle of double-sided double point overcurrent welding. During operation, two electrodes pressurize the workpiece, causing a certain contact resistance between the two layers of metal under the pressure of the two electrodes, and the welding current flows from one electrode to the other. Instantaneous hot melt is formed at two contact resistance points, and the welding current flows from the other electrode to the electrode along the two workpieces, forming a circuit without damaging the internal structure of the workpieces to be welded. Circular tube spot welding machine is used for spot welding of thin plates. Suitable for spot welding of circular pipe joints, it saves the steps of undercutting and jointing, and the spot welding effect has strong robustness.

Performance Feature

The chassis is made of high-strength steel plate, structural design originally from Japan, the control box design adopts the principle design of the original Japanese control box and the original Taiwan circuit boards for assembly, with constant current, constant voltage function for choice. Control box with grid voltage compensation function, there are three sections of current can be selected, and can store 15 kinds of welding specifications, current slow rise, slow fall, etc

Machine Parameters

| Model | Electrode Force Length(mm) | Thickness(mm) | Input Voltage(V) | Power | Weight(kg) | Dimensions(mm) |

| WY-PD-40 | 400 | 2+2 | 380V/50HZ | 0.75KW | 200 | 1100*600*1400 |