Description

Product Description

Corner making machine realizes automatic production and simple operation, which not only saves labor, but also is more safe and reliable. It mainly completes uncoiling, leveling, feeding, punching and forming, and it can produce 45 complete corner codes per minute on average.

Basic Components

1.One electric discharge frame;

2.One unit of leveling machine;

3.One unit of feeding mechanism;

4.One punching machine;

5.A set of molds;

6.A set of computer control system.

Performance Feature

Punch press: high-precision pneumatic punch press, controlled by service feeder, with relaxation structure. Mitsubishi brand PLC. The conveying accuracy is 0.02 mm. High-precision progressive die without waste, the punching thickness is 0.8-1.0mm, 1.0-1.2mm (either) bears 1100KG of gravity, the motor automatically controls the material transfer, and the touch screen control of independent electric box realizes the functions of output counting, target counting, fault alarm and material shortage monitoring.

Machine Parameters:

| Model | Pressure | Thickness | Power | Slide Stroke | Die Set Height | Weight | Dimensions |

| WY-JM-63 | 630KN | 1.2mm | 9 KW | 110mm | 360mm | 3800kg | 1810*1350*2740mm |

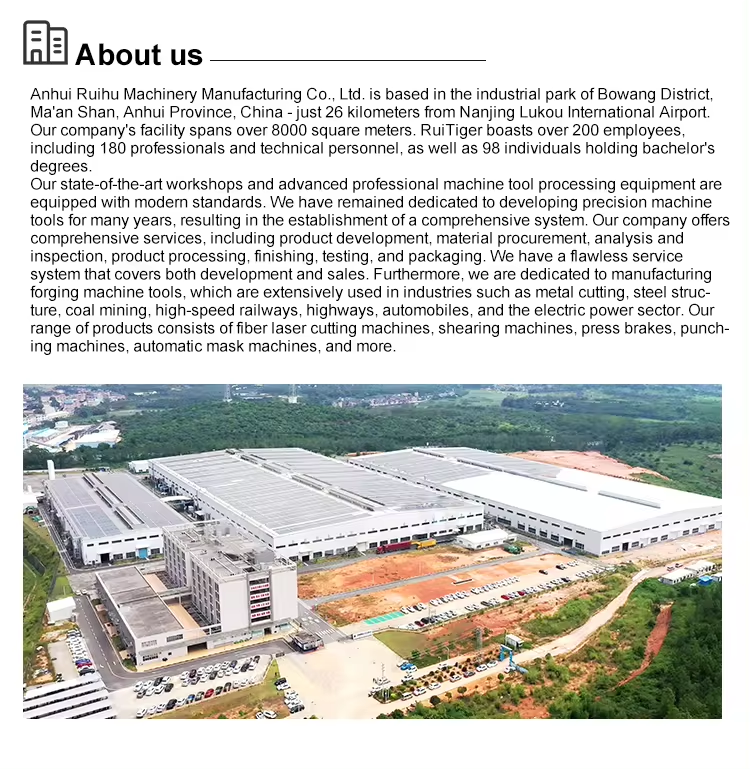

Q:Is your company a trader or a factory?

A:We are a factory and have an independent trading department.

Q:Where is your company? Can I come and visit?

A:Our company is located in Maanshan City, Anhui Province, China, welcome to visit us.

Q:What is your payment method?

A:Bank transfer, or Alibaba online payment.

Q:Does your company provide after-sales service? What kind of after-sales service?

A:We provide one year warranty service and free replacement of non-man-made damaged parts.

Q:How long does it take to receive a reply to my inquiry?

A:We will reply your inquiry within 24 hours (working days).

Q:What are your working hours?

A:9am-5pm (weekdays).

Q:How is your quality control?

A:Every machine that comes out of the factory will go through strict testing to ensure that it reaches the customer and can be used normally.

Q:Do you support customization? Can I put my logo on the product?

A:Yes.

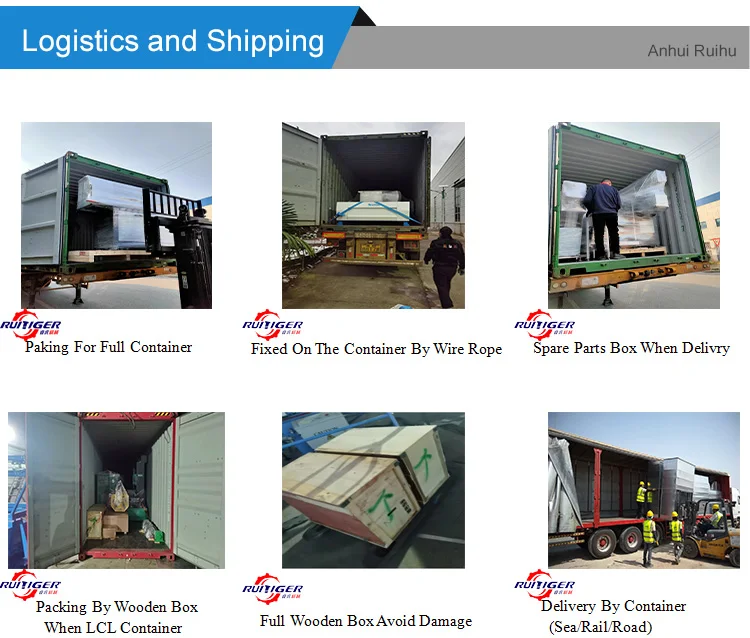

Q:What is the packaging of the product?

A:The machine is wrapped in plastic material and placed inside a customized wooden box.

Q:What is the minimum order quantity?

A:One piece.

Q:What information do I need to provide to get a quote? Do you have a quotation for the products?

A:Please provide the approximate length and thickness of the workpiece to be processed, please contact our customer service for details.

Q:How long is the delivery time?

A:Production is completed within two weeks.