Description

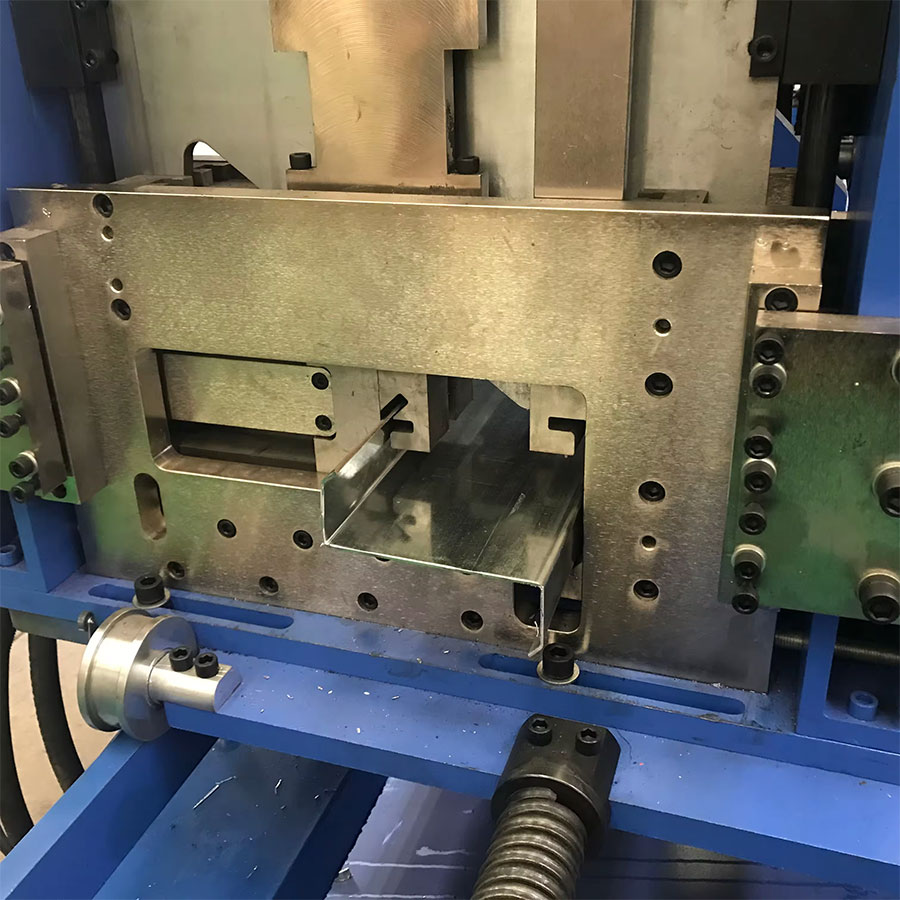

The Roll Forming Machine is composed of feeding, forming, and post-forming cutting. The plate produced has a flat and beautiful appearance, high strength, and durability. It is widely used in industrial and civil buildings, such as factories, warehouses, gymnasiums, exhibition halls, theaters, etc. House surfaces and walls.

Technical parameters of corrugated steel plate rolling machine:

|

NO.

|

Item

|

Data

|

|

1

|

Coil material

|

Q195/Q235

|

|

2

|

Material width

|

accoridng to size of profile

|

|

3

|

No of forming step

|

12

|

|

4

|

Forming speed

|

10-15m/minute

|

|

5

|

Thickness of side plate

|

30mm

|

|

6

|

Material of shafts

|

45# steel with tempering

|

|

7

|

Thickness of feeding material

|

1.0mm -3.0mm

|

|

8

|

Material of rollers

|

Gr15 heat treatment with chrome

|

|

9

|

Cutting type

|

Hydraulic cutting

|

|

10

|

Main power

|

15kw

|

|

11

|

Brand of motor

|

China

|

|

12

|

Main frame

|

300H steel

|

|

13

|

Control system

|

PLC Computer

|

|

14

|

Manual Uncoiler

|

5 Tons

|

|

15

|

Power

|

3phase,380voltage,50hz

|

|

16

|

Dimensions(L*W*H)

|

About10*1.4*1.8M

|

|

17

|

Weight

|

About 9.0 tons

|

Whole in one piece to save space and shipment cost.